THE QATSPY® The Quapaw Aviator Tiger Services & Patrol

By: Charles W. Boatright, President of THE GREAT QATSPY® Company

Typical Aerial Patrol of the Power Grid– One of the Most Important Jobs we in Power Utilities have is performing Aerial Patrols of the Grid. Aerial Patrols helped Sustained Reliable to Communities for Economic & Environmental Issues.

The feature photograph was one that I took in the Fall of 2010 on the Cleveland – Drew 115kV Line near Drew, Mississippi. Drew is where Archie Manning is from, father to Cooper, Payton, and Ely, that played for Ole Miss. Charlie Pride was from Sledge, Mississippi just north of this line. The Fall aerial patrols were the most enjoyable to fly due to nice harvest time temperatures and the Fall colors that I tried to capture.

Most of our country’s power grid was built during the 1930’s and 40’s with wooden construction at the time with a H-Frame configuration in most cases. This means that these wooden components are approaching 90- years of service life that we try to maintain in piecemeal fashion for the first part of my career in the 1990’s.

Even with a trained eye flying at 50- knots (58 mph), you can’t determine the reliability of 80-to-90 year old structure with wood components. What has changed since these lines were constructed is the higher demand for uninterrupted service with our customers integrated computerized systems. Some manufacturers we serve can’t even operate if there is a flicker on their service feed or especially a trip-&-Reclose.

If these type interruptions occur, our major manufacturing customers would have to shutdown and reset all their computer operations after these type incidents. I have answered a many of calls at night from major accounts concerning these interruptions. Then I would had to fly the line to determine the cause. Below, I’m pictured after completing my last aerial flight that I took in May of 2015, before retiring in June of that year.

The photograph below and in the featured photograph above that I took, are some of the typical issues we had with wooden poles components where the X-arms are cracked or decayed, featured image above; or the X-brace fails or came unbolted from the structure that weakens the integrity of the entire structure, shown below.

The other issue that utilities are facing is undersized stranded capacity of existing lines that are being taxed beyond their original design. The last decade that I worked with Energy Corp, we had an emphasis on rebuilding the system Grid to be a more hardened Grid due to the elements and loading. As a Grid Engineer, I had rebuilt over 250 miles of line before retiring in June of 2015. Just to give you an idea of how many structures that entails, there are approximately 8 structures to the mile usually with 2- poles-construction.

Also a transmission lines voltage (69kV to 500kV) due to feasibility can’t be directly buried, the cost would be extremely prohibited with current technologies. Also for a power source to be consider as base load for a system has to supply a minimum of 45 percent of the Grid System Load. As of this date, wind and solar only accounts for ~14 percent and isn’t reliable due to generation periods.

Wood Poles and X-arms Reclamation Project

We usually replace the wooden H-Frames with either steel or concrete single pole construction on the existing right-of-way that has several advantages. One– You’re not purchasing additional right-of-way, Two– You are replacing wood that is susceptible to decaying with coated steel or concrete. Third– You’re bringing in and raising the conductors that avoid vegetation outages. Eighty-seven percent of all outages are caused by vegetation from off the right-of-way.

So if we rebuild a wooden line, we have the issue of deposing of wooden poles that are 65- feet or longer. Take the average rebuild of 30- miles times 16 poles per mile, that is 480 wood poles to dispose or repurpose as we prefer of for an average project.

Repurposing Wooden Poles with Environmental Reclamation Project

Typically, we try to give the good condition poles to municipalities and schools for ball fields and other structure components. The other wooden poles we like to give to the landowner, farmer, or rancher. But the problem is that we still have poles lifted over, some 200 of them. For Environmental purposes, we avoid depositing them in landfills that is very costly.

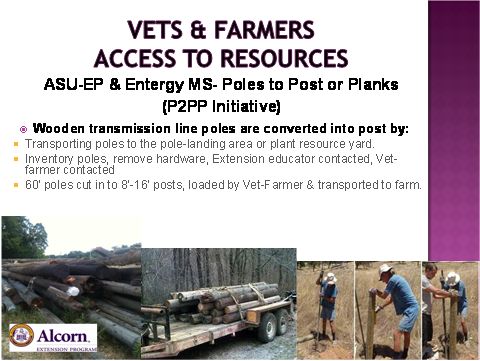

So in 2009, I had the fortune and pleasure of meeting Ralph Arrington with the ALCORN State University Extension Service that deals with small farmers and ranchers that are military veterans. These Veterans are transitioning into agriculture for their new civilian careers. One great advantage of this program is that Veterans are great with resources and their use. I also worked with Chuck Upchurch with our Environment Section with Entergy Corp in developing a reclamation procedure for wood poles.

With his help and help from Ralph Arrington over the entire state of Mississippi, I was able to have these farmers using log trucks come and pick them up at about 12-15 poles per load. They used these wooden poles for pole barns, corals, fencing, piles for bridges, and other farm and ranch needs. These poles are not intended for personal dwellings or furniture use due to the treatment. But are great for approved purposes listed in the specifications that we developed in 2009 a procedure with Ralph Arrington.

This is a WIN-WIN-WIN

This Wood Pole Reclamation Program that I was proud to be a part of in 2009 was a WIN for the Farmers and Ranchers of Mississippi, WIN for the company reducing the cost of the project for disposal, and WIN for the environment keeping wooden poles out of landfills. This program can be replicated in others grids and states.

Part of my degree was in Environmental Engineering where we as grid engineers are conscious of the environmental impact our projects have while also providing reliable and sustainable power to our customers. I was proud of the work I did with Chuck Upchurch in this Reclamation Project for the company with Ralph Arrington, with Alcorn State University, but more importantly, the impact this project has on the agriculture industry that makes up the large part of the Mississippi economy.

It was a pleasure for me to work with Chuck Upchurch and Ralph Arrington on this vital project that helps so many people in our community.

ALCORN State University Ralph Arrington, who I had the pleasure of working with, works with ALCORN State University that is located just north of Natchez, Mississippi off U.S. Hwy 61.