THE BOATRIGHT Kosciusko Khaki & Blues REPORT- A Back Road Guide to (AI) American Ingenuity

By: Charles W. Boatright, President of THE GREAT QATSPY® Company

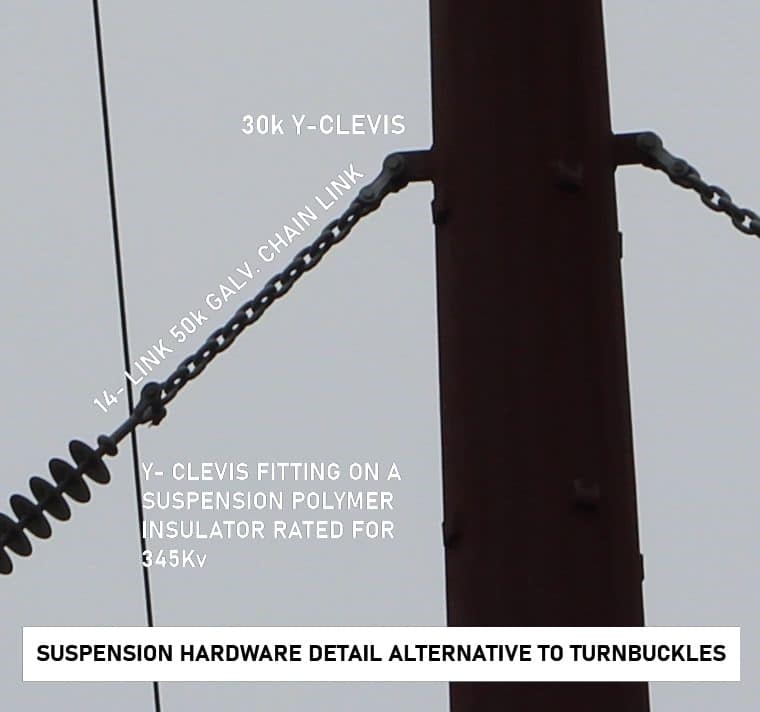

Chain Link a Simple Retrofit to the Turnbuckle– A Design Revision I made after Linemen Noticed Suspension Turnbuckles Backing off Tension

In the past few articles that I have written, I described the work that I did as Grid Engineer for the Mississippi Grid with Entergy Services, in view of recent events that took place in Maui that were catastrophic in nature. No words can describe those events that could have been avoided if proper measures and procedures were in place.

The Electrical Grid impacts our lives in a number of ways, beyond just providing power to our communities, but also the safety of public. Engineering and line work by linemen are the unsung heroes of our electric grid that provides reliable power, but also safety to our public that we serve. Safety was the driving component of our design, construction, and maintenance work that also included vegetation clearing.

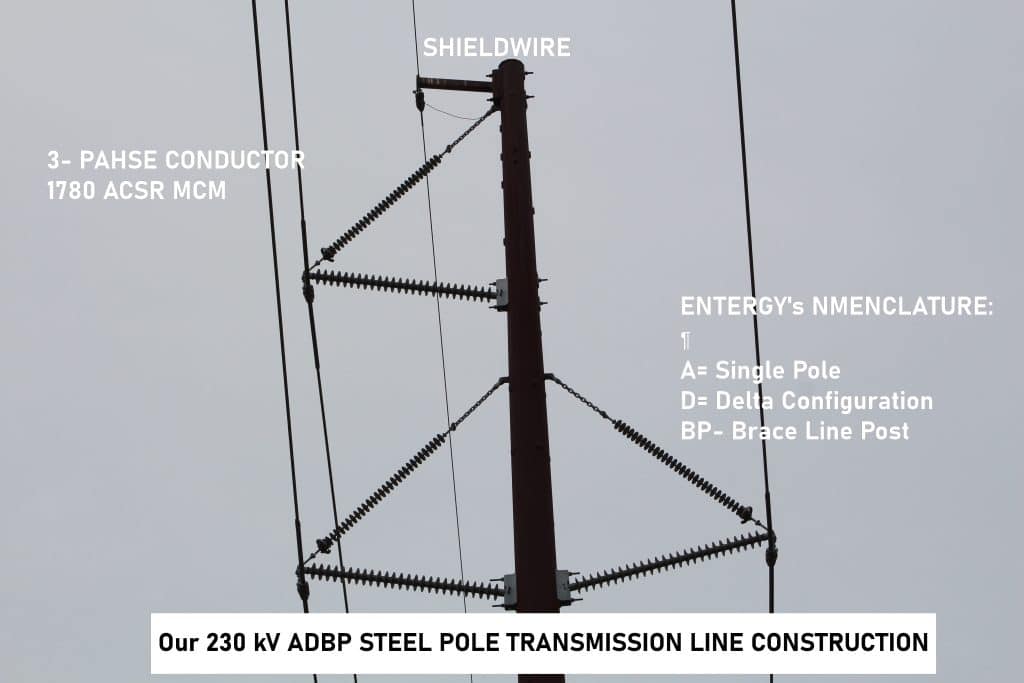

We, in the early 1990’s, started transitioning from wooden pole construction to either spun cast concrete or steel pole construction to reduce the maintenance issues and provide a longer span life of service. When climbing inspection reports would come across my desk from our six line crews, I read them to plan for future maintenance work, but more importantly to effect design changes that we could implement to make our system more reliable and safer.

A Hardware Issue that became an Issue

I was noticing linemen were making notes on their inspection sheets indicating that they had to tighten turnbuckles that was recently installed that had backed off of the Brace Line Post insulators assembly. What was alarming was that this type of suspension assemblies had just been in place for just a couple of years.

Vibration that occurs on the long spans, especially on transmission structures with large conductor like 1272 or 1780 ACSR conductors, causes the turnbuckle to back off from the suspension of the insulators. This caused the Brace Line Post to carry the majority of what we call the Weight Span load of the conductor that it wasn’t designed to carry.

Weight Span is from maximum sag in the back span to the maximum sag in the span ahead. That could be up to 1,517 lbs vertical load, plus any ice loading per insulator. Ice loading occurs during an ice storm where ice accumulates on the conductor. Coupled ice load with impact from galloping cause by the right type wind conditions, that can occur under special situations, then vertical loading could be twice that of the normal suspended load to include a impact load.

This lack of bracing for the Brace Line Post by the loose turnbuckle could introduce a fatigue factor into the brace part of the fiberglass rod of the insulator, denoted above and below in these two photographs. This would lead to the insulator failing and dropping the conductor, which in itself is bad enough, but an energized conductor, on a 230 kV Line with 3,000 amps, shown above, being dropped is catastrophic event, in regard to the public safety. This is something no Grid Engineer wants to think about, that we have nightmares at night.

A Simple Fix to the Turnbuckle Problem

I personally never liked turnbuckles, for either suspension or deadends applications, due to the adjustable component of these that have the tendency of backing off of the turnbuckle tension. I finally got my chance to change the design when I was named to head up the Transmission Standards for the entire Entergy System in 1994.

So I contacted my buddy Jeff Miller with Stuart C. IRBY to order me a barrel of 200 foot length of 50k Strength Galvanized chain that we could cut to length to retrofit the turnbuckle. We tested this retrofit chain linked suspension in various locations around the system. A simple retro fix was a simple installation that the linemen appreciated, by not wasting time tensioning and back bolting three turnbuckles per structure, shown below. It also saved money of having to purchase the much more expensive turnbuckle.

Needless to say, the 50k Galvanized Chain Link became an instant success among our line crews and was part of our standard design for Brace Line Post suspension which is still being used today after its introduction in 1995. Soon after I worked three (3) years in Transmission Standards, I had to get back out into the field and lose the tie and sports jacket for khakis shirts and blue jeans with my cowboy boots and my A-2 or G-1 Leather Bomber Jacket, up until I retired in June of 2015. I now operated an aviation apparel business that includes the A-2 and G-1 Leather Bomber Jackets and khaki Chino pants with other gear, as noted below, use link to shop:

Aerial Patrol to Detect Potential Line and Safety Issues

One of the precautions that I took as the Mississippi Grid Engineer, after leaving Standards and getting back into the field, was to fly the entire system of 2,850 miles of transmission line in Mississippi after an ice storm or hurricane. To some, that would seem to be a waste of time and money, but it wasn’t in three cases that I found.

But if others had seen what I have witnessed after just three (3) storm patrols in particular, they would attest it was money well spent in saving lives, especially of kids in one case. I found in the aftermath of three storm patrols where the conductor was unpinned and dropped the conductor 3- feet off the ground.

In one case after an ice storm in 1997, I found where a 115kV energized conductor north of Batesville, Mississippi was suspended just 4 feet off the ground in a pasture where kids were playing. I immediately landed the helicopter in the adjacent field and called dispatch to have them switch out that line segment. Then I threw up because I knew what could had happen and the consequences could have been to those kids playing and impact of what I could have witnessed.

That was how serious we took the work that we did when we were working Transmission Line Construction/Maintenance. Safety was in front of everything we did, and there was no room to compromise, not even for special interest group like influenced Hawaii Electric.

I wanted to convey this story to the public after what occurred in Maui. That was not our routine method of operations in Mississippi and other parts of our country. Engineers and linemen are conscious of the work we do and the service we provide to our communities. I have a great friend that I grew up with in North Little Rock, Arkansas whose nickname is Cowboy. He was over all line operations for the city of North Little Rock and would agree with this assessment of our work integrity.

There is no place for alternative priorities in our work we conducted, not even to special interest groups. Outside forces should never dictate design, safety procedures, or power production to those in the utility business. We just witnessed what happens when this is the case when outside interest drive utility operations. Do you think those special interest will be in the class action suit? the Answer is No! These are catastrophic consequences, as experienced in Maui, shows how compromising standard practices impacts the safety of the public.

If you see a suspended or on Down conductor on the ground: FIRST- Don’t go near it considered it LIVE; and SECOND- Call 911 to report it or call your utility if you have their number.